In today's fast-paced industrial landscape, efficient bulk material packaging has become a critical factor in maintaining competitive advantage. An advanced jumbo bag packing machine represents the pinnacle of automated packaging technology, designed to streamline your operations while ensuring precision, safety, and cost-effectiveness in handling bulk materials across diverse industries.

Understanding Jumbo Bag Filling Technology

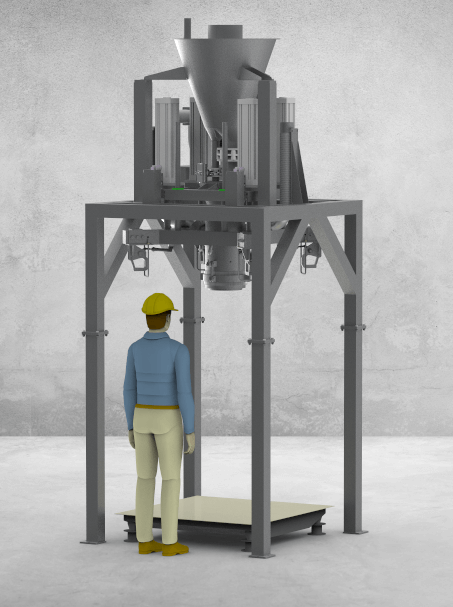

A jumbo bag packing machine, also known as a big bag filling machine or FIBC (Flexible Intermediate Bulk Container) filling system, is sophisticated industrial equipment engineered to automatically fill large-capacity bags with powdered, granular, or free-flowing materials. These advanced systems have revolutionized how manufacturers, distributors, and processors handle bulk commodities, eliminating manual labor inefficiencies while dramatically improving workplace safety and product quality.

The technology behind these filling stations combines precision weighing mechanisms, automated material discharge systems, and intelligent control panels that work in perfect synchronization. Modern bulk bag filling equipment utilizes load cells for accurate weight measurement, pneumatic or mechanical bag inflation systems, and programmable logic controllers (PLCs) that ensure consistent filling operations throughout your production cycle.

Key Components of Industrial Bag Filling Systems

Weighing and Dosing Mechanisms

At the heart of every high-performance jumbo bag packing machine lies an advanced weighing system. These precision instruments employ multiple load cells strategically positioned to capture real-time weight data during the filling process. The weighing platform typically features a robust construction capable of supporting loads ranging from 500 kg to 2000 kg or more, depending on your application requirements.

The dosing mechanism works in tandem with the weighing system, controlling material flow through adjustable gates, valves, or feeders. Many modern systems incorporate two-speed filling technology: a fast fill mode for efficiency and a slow dribble feed for precision as the target weight approaches. This dual-speed approach minimizes product giveaway while maximizing throughput, directly impacting your bottom-line profitability.

Bag Inflation and Positioning Systems

Proper bag preparation is crucial for successful filling operations. Advanced big bag filling machines incorporate pneumatic bag inflation systems that gently expand the FIBC before material discharge begins. This pre-inflation process eliminates bag wrinkles, ensures uniform filling, and prevents material bridging or uneven distribution within the container.

The bag positioning framework typically includes adjustable spout holders, bag lifting loops attachment points, and centering guides that secure the jumbo bag throughout the filling cycle. Many premium models feature operator platforms with ergonomic working heights, making bag attachment and removal safer and more efficient for your workforce.

Material Discharge and Dedusting Solutions

The material discharge system varies based on the characteristics of your product. Free-flowing materials may utilize simple gravity-fed hoppers, while challenging products like fine powders or cohesive materials might require vibration assistance, air fluidization, or mechanical agitation to maintain consistent flow rates.

Dust collection and containment represent critical considerations in bulk packaging operations. Integrated dedusting systems capture airborne particles during the filling process, protecting worker health while preventing product loss and maintaining facility cleanliness. These systems typically connect to your existing dust collection infrastructure or operate as standalone units with replaceable filter cartridges.

Types of Jumbo Bag Filling Machines

Open Mouth Filling Systems

Open mouth big bag fillers represent the most versatile and widely used configuration in industrial packaging. These systems accommodate standard FIBC designs with open tops, filling through a spout connection or direct discharge into the bag opening. The simplicity of open mouth filling makes it ideal for free-flowing products like plastic pellets, grains, minerals, and chemical compounds.

Modern open mouth filling stations often incorporate densification features such as vibration tables or pneumatic hammers that settle material during filling, maximizing bag capacity and creating stable, transportable packages. Some advanced models include bag cinching mechanisms that automatically close and secure the bag top after filling completion.

Valve Bag Filling Equipment

For applications requiring hermetically sealed packaging, valve bag filling technology provides an excellent solution. These specialized systems insert a filling tube into the bag's valve opening, delivering material while maintaining a closed environment that protects sensitive products from moisture, contamination, or oxidation.

Valve bag fillers excel in handling cement, construction materials, chemicals, and food ingredients that require extended shelf life or enhanced product protection. The filling process automatically closes the valve through material pressure or mechanical action, eliminating the need for additional sealing operations.

Vacuum Filling Systems

Vacuum-assisted big bag filling machines utilize negative pressure to draw material through transfer lines and into waiting containers. This technology proves particularly valuable for conveying materials over long distances, handling heat-sensitive products, or processing in cleanroom environments where dust generation must be absolutely minimized.

Pharmaceutical manufacturers, food processors, and specialty chemical producers frequently employ vacuum filling systems due to their gentle product handling characteristics and superior contamination control capabilities. The enclosed transfer process also prevents exposure to ambient moisture or atmospheric contaminants that could compromise product quality.

Industries Benefiting from Automated Bulk Bag Filling

Chemical and Petrochemical Manufacturing

Chemical producers rely heavily on jumbo bag packing machines to safely handle diverse compounds ranging from basic industrial chemicals to specialized formulations. These systems accommodate corrosive materials, hazardous substances, and high-purity products while maintaining strict safety protocols and regulatory compliance.

The automated nature of modern filling equipment minimizes human contact with potentially dangerous materials, reducing workplace accident risks while ensuring consistent packaging quality. Explosion-proof designs and inert gas purging capabilities enable safe handling of reactive or flammable substances.

Food and Beverage Processing

Food-grade big bag filling machines meet stringent sanitary design requirements essential for protecting consumable products. Stainless steel construction, tool-free disassembly for cleaning, and compliance with FDA and USDA regulations make these systems suitable for packaging flour, sugar, starches, dried ingredients, and numerous other food commodities.

Contamination prevention features including dust-tight seals, positive air pressure, and sanitizable surfaces ensure your products meet food safety standards throughout the packaging process. Many systems also incorporate metal detection or X-ray inspection to verify package integrity before final dispatch.

Agricultural and Feed Production

Agricultural operations utilize bulk bag filling equipment to package seeds, grains, fertilizers, and animal feed products efficiently. The rugged construction of agricultural-grade filling machines withstands harsh production environments while maintaining reliable performance through seasons of continuous operation.

Variable capacity settings allow processors to fill different bag sizes as market demands shift, providing operational flexibility that enhances profitability. Weather-resistant designs enable outdoor installation when facility space limitations exist, expanding your packaging capabilities without major capital investments in building expansion.

Construction Materials and Mining

The construction and mining sectors depend on jumbo bag filling technology to package cement, sand, aggregates, minerals, and specialized construction compounds. Heavy-duty filling systems handle abrasive materials that would quickly wear out lighter-duty equipment, delivering years of reliable service in demanding applications.

High-speed filling capabilities process large production volumes efficiently, keeping pace with upstream processing equipment while minimizing packaging bottlenecks. Dusty materials common in these industries benefit from powerful dust collection systems that maintain clean working environments and reduce product waste.

Pharmaceutical and Nutraceutical Manufacturing

Pharmaceutical-grade big bag filling machines incorporate advanced features that prevent cross-contamination between product batches, maintain controlled atmospheres, and provide complete documentation of filling operations for regulatory compliance. These precision systems handle active pharmaceutical ingredients (APIs), excipients, and nutritional supplements with the accuracy and cleanliness pharmaceutical production demands.

Cleanroom compatibility, automated cleaning-in-place (CIP) systems, and validation documentation support your quality management objectives while streamlining production workflows. Integration with serialization and traceability systems ensures complete supply chain visibility for regulated products.

Advanced Features Enhancing Operational Efficiency

Programmable Logic Controllers and Automation

Modern jumbo bag packing machines leverage sophisticated PLC technology that transforms basic filling operations into intelligent, self-optimizing systems. These controllers manage every aspect of the filling cycle, from initial bag detection through final weight verification and automatic cycle advancement.

User-friendly human-machine interfaces (HMIs) with touchscreen displays simplify operation, allowing workers to adjust parameters, monitor performance metrics, and troubleshoot issues without specialized technical training. Recipe management systems store filling parameters for multiple products, enabling quick changeovers that minimize downtime between production runs.

Real-Time Monitoring and Data Analytics

Integration with enterprise resource planning (ERP) and manufacturing execution systems (MES) provides unprecedented visibility into your packaging operations. Real-time data collection tracks key performance indicators including throughput rates, accuracy statistics, downtime events, and material consumption, empowering data-driven decision making that continuously improves operational performance.

Predictive maintenance algorithms analyze equipment performance patterns, identifying potential failures before they occur. This proactive approach minimizes unplanned downtime while optimizing maintenance schedules based on actual equipment condition rather than arbitrary time intervals.

Multi-Level Safety Systems

Comprehensive safety features protect both operators and equipment throughout the filling process. Emergency stop buttons at multiple locations provide immediate shutdown capabilities, while safety interlocks prevent operation when guards are open or bags are improperly positioned.

Overload protection prevents damage to weighing components, while automatic fault detection systems identify and diagnose operational issues, often resolving minor problems without operator intervention. Some advanced systems incorporate machine vision technology that verifies proper bag positioning before initiating the filling sequence.

Selecting the Right Jumbo Bag Filling Solution

Capacity and Throughput Requirements

Accurately assessing your production volume needs represents the first critical step in selecting appropriate filling equipment. Consider both current production requirements and anticipated future growth when evaluating capacity specifications. Undersized equipment creates production bottlenecks, while oversized systems represent unnecessary capital expenditure.

Throughput specifications typically range from 10 to 100 bags per hour, depending on bag size, product characteristics, and accuracy requirements. Systems handling free-flowing materials generally achieve higher throughput rates than equipment processing challenging products requiring special handling techniques.

Product Characteristics and Handling Requirements

Different materials exhibit unique flow properties, bulk densities, and handling sensitivities that influence equipment selection. Free-flowing products like plastic pellets require simpler filling systems compared to cohesive powders or hygroscopic materials that absorb atmospheric moisture.

Temperature sensitivity, abrasiveness, toxicity, and explosion risk all factor into equipment specification decisions. Providing detailed product information to equipment suppliers ensures they recommend systems properly configured for your specific applications, avoiding costly mistakes and operational headaches.

Integration with Existing Production Lines

Modern big bag filling machines integrate seamlessly with upstream processing equipment and downstream palletizing or conveying systems. Considering material flow throughout your entire production facility optimizes overall efficiency rather than creating isolated improvements that shift bottlenecks elsewhere in your operation.

Compatibility with existing control systems, power supplies, and facility infrastructure affects installation costs and commissioning timelines. Early engagement with equipment suppliers during the planning phase identifies potential integration challenges while solutions remain manageable and affordable.

Budget Considerations and Return on Investment

While initial equipment cost represents an obvious consideration, total cost of ownership provides a more comprehensive evaluation framework. Factors including energy consumption, maintenance requirements, spare parts availability, and expected equipment lifespan significantly impact long-term ownership economics.

Calculate potential return on investment by quantifying labor savings, reduced product giveaway, improved throughput, and enhanced product quality. Many organizations discover that premium equipment with advanced features delivers superior ROI compared to basic systems despite higher upfront costs.

Installation, Commissioning, and Operator Training

Proper installation establishes the foundation for reliable long-term equipment performance. Professional installation teams ensure level mounting, proper electrical connections, appropriate dust collection integration, and thorough functional testing before releasing equipment for production use.

Comprehensive operator training maximizes your investment by ensuring personnel understand proper operating procedures, routine maintenance tasks, basic troubleshooting techniques, and safety protocols. Well-trained operators identify potential issues early, preventing minor problems from escalating into major failures that halt production.

Maintenance programs incorporating regular inspections, calibration verification, and preventive component replacement extend equipment lifespan while maintaining filling accuracy and operational reliability. Establishing partnerships with equipment suppliers for ongoing technical support provides peace of mind and rapid response when unexpected issues arise.

Conclusion

Investing in a high-quality jumbo bag packing machine transforms your bulk material handling operations from labour-intensive manual processes into streamlined automated systems that deliver consistent results day after day. The right big bag filling solution reduces operational costs, improves workplace safety, enhances product quality, and provides the scalability your growing business demands.

Whether you're packaging chemicals, food ingredients, agricultural products, construction materials, or pharmaceutical compounds, modern bulk bag filling technology offers customizable solutions tailored to your specific requirements. By carefully evaluating your production needs, product characteristics, and operational objectives, you can select filling equipment that delivers measurable value throughout its service life.

The weighing and packaging solutions available at weighnpack.com represent proven technology backed by engineering expertise and customer support that ensures your success. From initial consultation through equipment selection, installation, and ongoing service, choosing the right partner makes all the difference in achieving your operational goals and maintaining competitive advantage in your market.

Take the next step toward packaging excellence by exploring the comprehensive range of jumbo bag filling machines designed to meet the diverse needs of modern industrial operations. Your investment in quality automated filling equipment pays dividends through improved efficiency, reduced costs, and enhanced product quality that strengthens customer relationships and drives business growth.